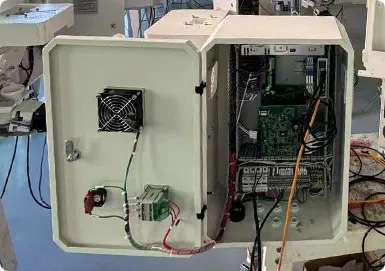

D-Batch( flagship model )

D-Batch Blender

D-batch Blender is applied in the field of extrusion. It is based on the industry 4.0 technology. It manages extrusion material control, extrusion process, and assists the technology department to manage the extrusion formula effectively.