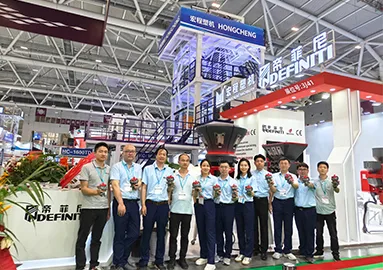

About DEFINITI

Professional manufacturer of extrusion control and raw material blending

DEFINITI was established in 2016, is a research and development, design, production, sales in one of the well-known national auxiliary machinery suppliers.Our products mainly cover Loss-In-Weight Feeder, Gravimetric Feeder, Automatic Air Ring, Online Thickness Gauge, Centralized Feeding System, etc. Up to now,we have accumulated over 12,000 sets of auxiliary extrusion equipment feeders, and have in-depth cooperation with many well-known host manufacturers in China.

After years of development, with the leading technical advantages and rich experience, Definiti has deeply cultivated the field of film blowing and casting, and has extensive cooperation in the fields of Film Coating, Extrusion Pelletizing ,Sheet Film and Plate, Wire drawing and so on.

Learn More